Why baseline matters

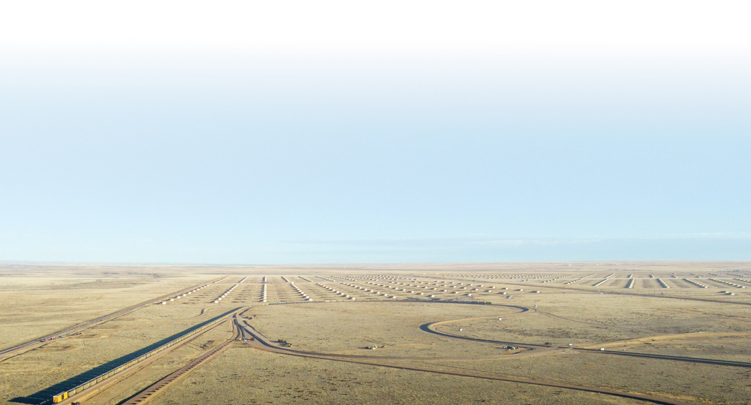

The Facility for Accelerated Service Testing (FAST®) Loop is a 2.8-mile test track in Pueblo, Colorado, designed to evaluate track components and systems before deployment in active service. Unlike operational railways where historical data may be incomplete or non-existent, the FAST® Loop offered a rare opportunity: to characterise ground conditions before construction began, then document the as-built state, and subsequently track changes over time.

This approach addresses a fundamental challenge in railway maintenance—distinguishing between inherent ground conditions, construction quality variations, and service-induced degradation.

Add subtext here if required

The pre-construction picture

Before trackbed construction in late 2023, a multi-technique geophysical survey mapped subsurface conditions to depths of approximately 10 metres. The survey combined:

- Frequency domain electromagnetic (FDEM) profiling to identify variations in ground conductivity, indicating changes in clay content or moisture levels

- P-wave seismic refraction to map layer depths and infer material types from velocity profiles

- Electrical resistivity imaging (ERI) to provide detailed resistivity structure at specific locations

- Multichannel analysis of surface waves (MASW) to estimate subgrade stiffness

The FDEM survey revealed generally dry, sandy soils across most of the loop, with conductivities between 3–10 mS/m. However, the southwestern corner showed significantly elevated values exceeding 30 mS/m—corresponding to a topographic low and the planned location of an overbridge and embankment. Rather than indicating clay-rich soils, this pointed to increased moisture content in the shallow subsurface.

Seismic refraction identified three distinct layers: poorly compacted surface materials (P-wave velocities 300–800 m/s extending to ~2m depth), intermediate mixed sands (extending to 5–7m), and stiffer materials interpreted as bedrock transition zones (velocities reaching ~2400 m/s).

The elevated conductivity near the planned overbridge prompted targeted MASW surveys to directly measure subgrade stiffness. These surveys confirmed the southwestern area exhibited notably lower shear wave velocities compared to other sections of the loop, indicating reduced material stiffness. This finding is potentially significant given the loading from both the overbridge structure and embankment fill in this area.

This pre-construction characterisation provided critical context for assessing construction impacts and establishing what “normal” looks like for this particular site.

Add subtext here if required

Post-construction assessment

Following track construction in early 2024, the survey techniques were repeated to document changes. Electrical resistivity imaging showed that the variable near-surface layer had been replaced with a uniform 2–3 metre thick zone of subballast and subgrade—characterised by resistivities consistent with dry granular materials. Below this engineered layer, resistivity actually increased slightly, possibly due to improved drainage or compaction effects from the overlying trackbed.

MASW surveys indicated increased Rayleigh wave velocities, confirming enhanced stiffness from the addition and compaction of trackbed layers. Importantly, the data also revealed slight increases in compaction of natural soils beneath the trackbed—evidence of construction-induced improvement extending beyond the engineered layers.

Beyond the subgrade: RASC® trackbed inspection

While geophysical methods characterised the foundation, the RASC® system provided comprehensive as-built documentation of the trackbed itself. Mounted on a hi-rail vehicle, the system integrated:

- Multi-frequency ground penetrating radar (200 MHz to 3 GHz)

- 2D linescan camera systems

- Mobile terrestrial laser scanning with integrated IMU

The resulting dataset included ballast fouling indices, layer thickness measurements, ballast particle size distributions, tie and fastener inventories, track geometry parameters, and georeferenced point clouds.

For a new-build track, results were largely as expected—the majority of the ballast classified as “Clean” with fouling indices below 5. Notable exceptions occurred near the overbridge approaches, where fouling indices reached 25–30, providing immediate feedback on trackbed quality variations.

The ballast thickness analysis also offered a useful quality metric. Summarised in 0.4-mile sections, it provided clear evidence of build consistency around the entire loop.

The value of repeat surveys

Six months after the baseline survey, repeat measurements began revealing the dynamic nature of trackbed systems. Ballast fouling index comparisons identified four locations with significant changes:

- Two areas showed increased fouling associated with known construction activities (grade crossing installation and concrete sleeper placement)

- Two others demonstrated reduced fouling attributed to trackbed maintenance

This ability to quantify change at specific locations transforms what might otherwise be anecdotal observations into measurable trends.

Looking forward

The FAST® Loop baseline surveys established a foundation for longitudinal studies linking subgrade properties, trackbed condition, and component performance under controlled loading. Future surveys during the loop’s operational life will track:

- Evolution of ballast fouling under accelerated wear conditions

- Changes in subgrade stiffness and moisture content

- Correlations between material property variations and track geometry deterioration and component wear

- Effectiveness of maintenance interventions

For the broader railway industry, this work demonstrates the feasibility of comprehensive baseline documentation for new construction and major renewals. Understanding natural ground conditions helps distinguish inherent variability from construction or maintenance issues. While the controlled environment of a test facility enabled thorough characterisation, the techniques themselves are readily deployable on operational railways.

As railway networks age and maintenance resources face increasing pressure, the ability to distinguish root causes from symptoms becomes ever more valuable.